Steel sheet and plate are fundamental materials in a wide variety of markets, especially in construction, production, and building. The difference between the two mainly lies in their thickness and the applications for which they are suited. Steel sheets usually vary in thickness from 1/16 inch to 3/16 inch, while steel plates encompass thicker materials varying from 3/16 inch to numerous inches thick. The convenience of steel sheets and plates makes them indispensable parts in the production of whatever from auto components and architectural structures to shipbuilding and machinery elements. Comprehending the residential or commercial properties, types, and applications of steel sheets and plates is vital for engineers, designers, and producers who depend upon these materials for their projects.

One of the most usual kinds of steel sheets is hot-rolled steel, which is created by rolling steel at heats, making it easier to form and develop. This procedure not just yields a vast array of dimensions and densities however also allows for the manufacturing of bigger sheets rapidly and effectively. One more preferred kind is cold-rolled steel, which goes through handling at space temperature, resulting in a smoother finish and improved mechanical homes. Cold-rolled steel sheets are typically made use of in applications where accuracy and surface area coating are essential, such as in devices and automobile components. In addition, there are specialized steel sheets, such as galvanized steel, covered with a layer of zinc to give boosted deterioration resistance, making it ideal for exterior applications, consisting of roofing and house siding.

Steel plates come in numerous grades, consisting of structural, aquatic, and abrasion-resistant, each with specific properties customized for various atmospheres and loads. The choice of the appropriate quality and type of steel sheet or plate is vital for ensuring the safety and security, performance, and durability of the final item.

The production of steel sheets and plates involves considerable processes consisting of cutting, bending, welding, and ending up. Welding is an additional vital procedure in the setting up of steel frameworks, calling for knowledge of different welding methods such as MIG, TIG, and stick welding. The completing procedure might consist of surface area therapies and coatings that enhance the material's resistance to rust, enhance looks, and lengthen service life.

The use of steel sheets and plates has evolved with advancements in innovation, leading to advancements such as high-strength low-alloy steels, which supply equal mechanical buildings to traditional grades while minimizing weight. The regular study and growth in the metallurgy of steel are concentrated on producing lighter, more powerful, and much more corrosion-resistant materials, which will further increase the adaptability and applications of steel sheets and plates in different markets.

Sustainability is a progressively essential consideration in the production and use of steel sheets and plates. Steel recycling has been an integral component of the sector for years, and the majority of new steel produced originates from recycled products. This process significantly lowers the carbon impact connected with steel production, aiding to attend to environmental concerns. In addition, makers are taking steps to optimize their procedures, minimizing waste and energy intake, straightening with worldwide sustainability goals. The capacity to create top quality steel while decreasing ecological impact not just benefits the planet yet likewise enhances the online reputation of business committed to lasting methods.

Steel plates offer as critical elements in bridge building and construction, with engineers making steel plate girders to support hefty loads and span lengthy distances. Furthermore, steel sheets are extensively utilized in erecting steel frameworks, providing versatility in layout while guaranteeing conformity with building codes and safety and security requirements.

In the production industry, steel sheets and plates create the backbone of a substantial number of items. From appliances to cars, the requirement for reliable and long lasting products is critical. Automotive producers make use of high-strength steel sheets to produce body panels that are light-weight yet incredibly resilient, which adds to enhanced gas efficiency without compromising safety and security. The home appliance sector benefits from cold-rolled sheets with improved surface area finishes, guaranteeing visual appeal while offering resilient durability versus day-to-day wear and tear. The integration of steel sheets in devices and equipment not just enhances the performance of items yet also prolongs their lifecycle, giving substantial value to producers and customers alike.

On an extra specialized note, the oil and gas industry's demand for steel plates is driven by the building of pipes and storage space facilities that must endure extreme environments and pressures. The demands for these products determine that they have high resistance to both deterioration and mechanical stress. Steel plates used in these applications are typically produced to exacting requirements, guaranteeing they can hold up against the roughness of transport and storage of diverse substances, including crude oil and natural gas. Furthermore, offshore boring systems are bordered by extreme aquatic problems, necessitating the use of marine-grade steel plates that guarantee structural stability and security.

Beyond industrial applications, the aesthetic utilization of steel sheets has located a home in building layout. Modern style welcomes innovation and advancement, integrating steel sheets not just for structural integrity but also for visual impact. Steel can be manipulated to develop vibrant exteriors, roof, and interior decoration aspects that celebrate the material's commercial heritage while offering modern appearances. Making use of corten steel, understood for its rustic patina, is particularly preferred in developing exterior sculptures and developing facades that blend into natural environments, showcasing the flexibility and beauty of steel in numerous style viewpoints.

When it comes to selecting distributors for steel sheets and plates, a number of variables should be considered to guarantee your tasks proceed efficiently. The credibility of the distributor, product array, quality guarantee processes, lead times, and client service are crucial aspects in picking a partner.

As we look towards the check here future, the role of steel sheets and plates will likely pivot in action to emerging innovations and products science. Advancements such as 3D printing, which has actually begun to penetrate traditional production worlds, may pave the way to brand-new applications for steel products and composites. Furthermore, innovations in wise products that react to ecological stimulations could result in the advancement of self-healing steel or products with boosted performance attributes. The total trend towards modular building and construction is most likely to further highlight the relevance of steel sheets and plates, as standardized components produce performance in assembly and decrease on-site building time.

To conclude, steel sheets and plates are necessary products that form the foundation for various applications throughout a varied variety of industries. From their vital duty in building and construction and manufacturing to their aesthetic contributions to contemporary design, these functional products remain to develop in action to technical advancements and sustainable methods. As sectors make every effort for innovation and environmental responsibility, the importance of understanding and choosing the proper steel sheets and plates will stay critical to accomplishing practical, economical, and lasting design services. Whether you are a supplier, developer, or building contractor , recognizing the indispensable duty of steel in your tasks will certainly not just improve performance however likewise add to the resilience and sustainability of our built atmosphere. As we progress, it is clear that steel sheets and plates will continue to form the future of design and style in amazing and cutting-edge means.

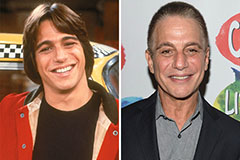

Tony Danza Then & Now!

Tony Danza Then & Now! Michael J. Fox Then & Now!

Michael J. Fox Then & Now! Ashley Johnson Then & Now!

Ashley Johnson Then & Now! Brandy Then & Now!

Brandy Then & Now! Rossy de Palma Then & Now!

Rossy de Palma Then & Now!